Paddle mixer of forced action for. Deviation 15 456 36 20 545 40 25 453 36 30 461 1.

Configuration Of The Mixer Showing The External Shell And The Plough Blade Download Scientific Diagram

Power input of 264 527 kWm 3 s for dt 20s Have 6 mixer chambers.

. Mixing required for flocculation mechanicallydriven paddles baffled channels G light dense floc Gt 10 5 10 -75 sec -1 10 Design Criteria. One minute mix The minimum dry mix time is 25 of one minute or 15 seconds. Some manufacturers have adapted their ribbon blender design by changing the agitator through the use of paddles or plows.

- R is the radius of the mixing tool center of shaft to tip of paddle in m. 10 Samples were analyzed for each mix time. Q Flow Rate GPM SG Specific Gravity μ Absolute Viscosity cps D Pipe Inside Diameter inches Step 3.

The time necessary for the chemical reaction in the mixer is approximately one or two minutes at typical rock fineness. Select the number of Elements Using the pipe Reynolds Number Re determined locate the proper flow regime and Re to select the number of elements required. Design of Agitators Mixers for Vessels with Drawing.

5 t 10 30 min contact opputinity in the basin small l arg e floc. Equation of cam displacement is written as follows. An industrial mixershaker with a fan blade fastened to a shaft and both coupled to the spindle of an electric motor was designed fabricated and tested.

Mixer stopped at 15 20 25 and 30 seconds after salt addition. Paddle mixer design calculation Written By buglisi Saturday April 2 2022 Add Comment Edit. We also have a handy calculator down below just plug in your information and well do.

The second step in the design sequence is the mechanical design of the mixer components. The mixer figure 1 for bulk materials mixing consists of a cylindrical drum 1 installed in the support element 10 which is fixed to the base 12. The experimental feed mixer is designed and.

By using this mixing formula you will see why the ASC Tornado is the most effective and efficient mixer on the market. R is the radius of the mixing tool center of shaft to tip of paddle in m n is the mixing speed in rpm. The ribbon tip speed can be calculated thanks to the following formula.

Two minute mix The minimum dry mix time is 25 of two minutes or 30 seconds. - n is the mixing speed in rpm. 1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 21-1 Direct-drive portable mixer.

The pumping capacity of an impeller is defined as the volumetric flow rate normal to the impeller discharge area. Mixing Calculators White Mountain Process is happy to provide these free mixing calculators for your use. For θ β 05 s 2hθ 2 β 2.

The mixer should be the bottleneck of the installation of mixing which means that it should not be slowed down by the process section upstream or downstream. Mixing Time1 Seconds Coef. The sound design of a double-shaft mixer with a horizontal shaft and rectangular buildings are given in the article on the basis of a priori review.

Courtesy of Lightnin mixers are mounted on the vertical centerline of a tank with baffles but may be off-center or off-center angle mounted. Cam is important factors in determining cam design Martin 1982. The result obtained show the Mixing force of 14715 N mixing volume of 0348 m 3 and required power by mixture of 243 hp.

713 Passive Mixer Design This section provides several methods to design straightforward but highly useful and effective RF mixers for many low-cost high-frequency consumer wireless products. Of Var2 Std. The power P consumed by an impeller is related to the volumetric circulation rate Q pumping capacity and the velocity Head Delta H from the impeller by.

Design consideration of this paper is to calculate Mixing Force Mixing Value belt tension and required power by mixer. Mixer Tests with F-500 Forberg Mixer. Single shaft ribbon mixer.

These are made available to help you do preliminary mixer sizing mixtank volume calculations some mixer mechanical design calcs etc. The fundamental approach is straight-forward design for power torque and speed then shaft loads and finally mixer dynamics. The mixer selection program allows you to calculate flow rates and power draw of mixing impellers see what.

For 𝜃 𝛽 05 ds dt 4hω β 1-θ β 2. 𝜃 𝛽 05 ds dt 4hωθ β 2. Power of 3 HP.

During loading and discharge the mixer speed must be such that the tip speed of the paddles is 1 ms. As with any practical design calculation at these frequencies parasitic capacitance. Fig1 Schematic diagram of the mixer material flow mixer inlet and outlet Mixer paddles are arranged in such a way that it takes to the content of the mixer one or two minutes to get to the other end.

There is a hatch in the lower part of the drum which is used to unload mixes and is closed by the cover 8 with the help of the lever 14. As a general rule of thumb we follow the formula described below for calculating the mixing rate in gallons per minute of material moved through our patented mixer blade. For smaller jobs the concrete made at the.

At the exit end there is an. Design the impact of decisions made at the process design step on the mechanical design requirements must be understood. The minimum wet mix time is 75 of two minutes or 90 seconds.

I offer a LISP based program to design and draw a detailed drawing of Agitator Mixer with user friendly dialog boxes which is an add-on for any CAD program for developing GA drawing for Agitator Mixer. 05 s h 1-2 1-θ β 2 1 Equation of cam velocity is written as follows.

Process Engineering Mind Mixer Mechanical Design Chemical Processing

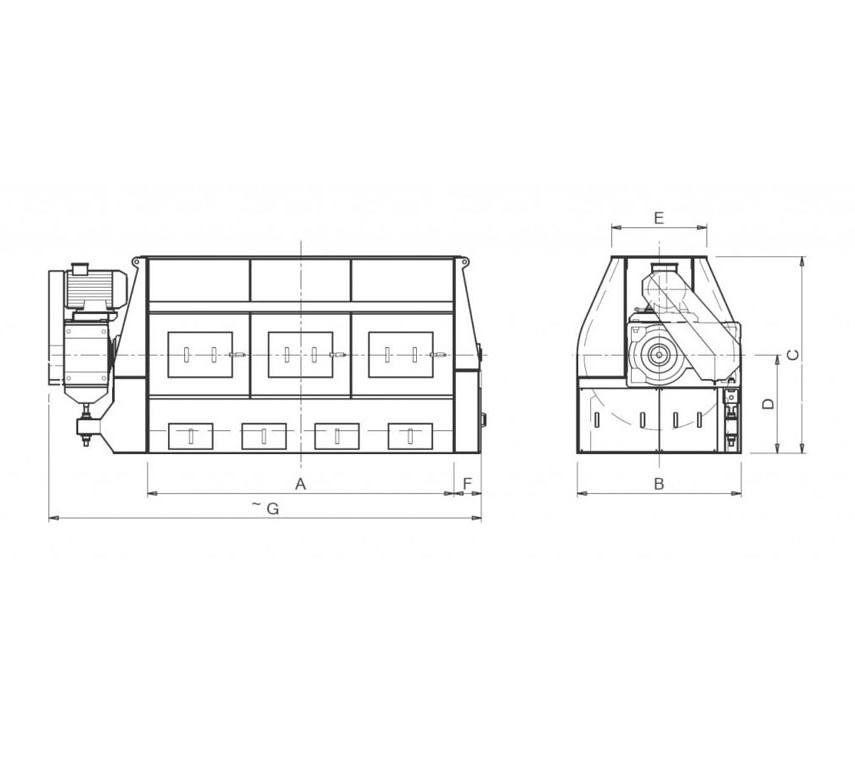

Paddle Mixers For Powders Double Shaft Paddle Mixers Twin Shaft Paddle Mixers

The Paint Machineries Were Using For Paints Diposing Purpose It Offer The High Speed Disperser It Is In Differet Different Si Machinery Manufacturing Sealant

Paddle Mixers For Powders Double Shaft Paddle Mixers Twin Shaft Paddle Mixers

What Measure Of Mixing Or Size Of Mixer Do I Need Xylem Dominica

The Geometry Of The Horizontal Ribbon Mixer With A Double U Shaped Download Scientific Diagram

Process Engineering Mind Mixer Mechanical Design Chemical Processing

Single Shaft Horizontal Mixer Feed Paddle Mixers Feed Mixer Fragola S P A

0 comments

Post a Comment